• Records on breakdowns and their causes. By means of previously recorded

breakdowns it is easier to compare the breakdowns and detect the reasons for

failure.

Beyond this, there are various institutions, associations and companies which carry out

series of measurements for different kinds of biogas plants. These series of measurements,

records and evaluations analyze errors with the objective to disseminate and optimize biogas

technology as well as to avoid mistakes of the past.

Repair

Breakdowns which might appear when operating biogas plants are described in the

following. The most frequently occurring disturbance is insufficient gas production which can

have a variety of different reasons. Sometimes observations and experiments might take

weeks until a perfect solution is found.

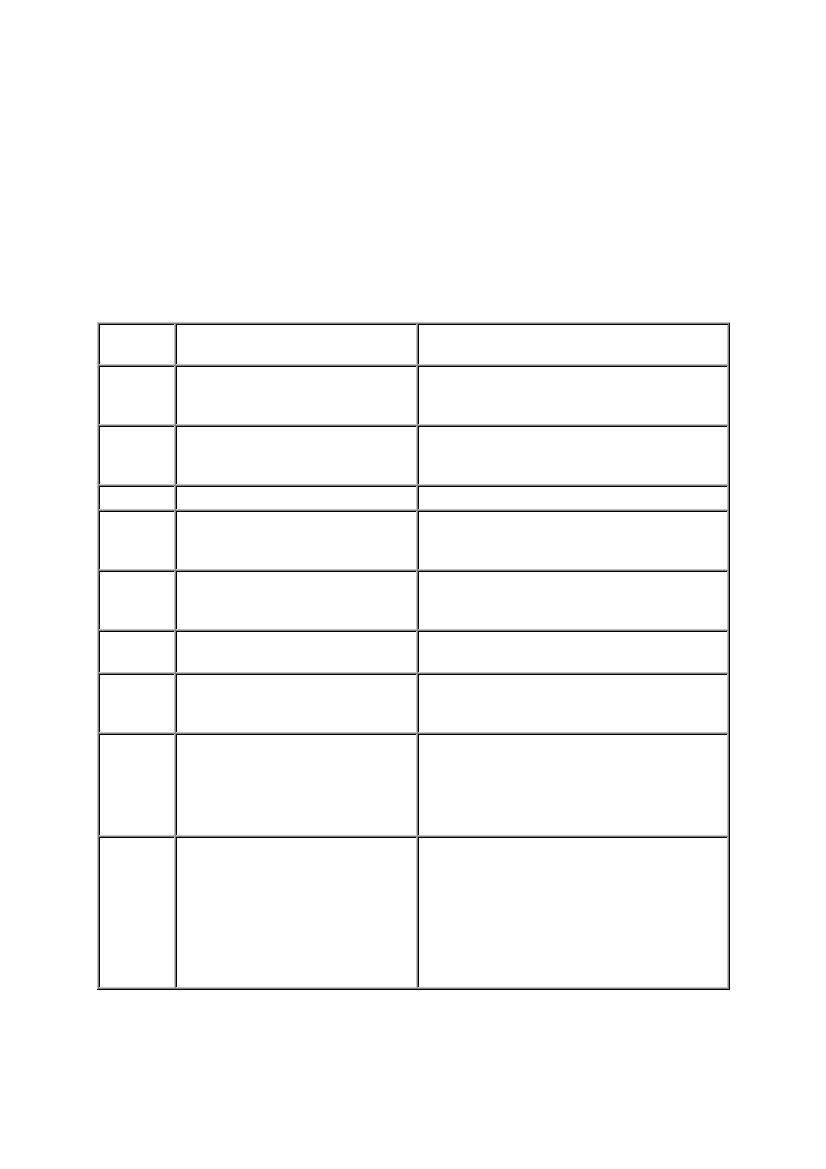

Disturba

nces

Possible reasons

Measures to be taken

blocked fibrous material inside the pipe or cleaning up the pipe with a pole; removing

inlet/outle sinking layer blocking the lower sinking layer by frequent ’poking’ through

t pipe end of the pipe

inlet and outlet pipe.

floating

drum is

stuck

swimming layer

turn the dome more frequently; if turning not

possible, take off the dome and remove the

swimming layer

broken guiding frame

weld, repair and grease guiding frame

sinking

sludge

level

digester not water-tight

if cracks in the digester do not self-seal

within weeks, empty digester and seal

cracks;

insufficie

nt gas

storage

gas store not gas-tight due to

cracks or corrosion

seal cracks, replace corroded parts;

blocked

taps

corrosion

open and close several times, grease or

replace taps;

gas pipe

is not

tight

corrosion or porosity; insufficient

sealing of connections;

identify leaking parts; replace corroded or

porous parts; re-seal connections

sudden

gas loss

8. crack in the gas pipe

9. automatic water trap blown

empty

10. open gas tap

4. repair or replace

5. add/refill water, detect reason for

over-pressure; check dimensioning

of the water-trap

6. close tap

throbbing

gas

pressure

1. water in the gas pipe

2. blocked gas pipe

1. check functioning of water trap;

install water traps in depressions of

piping system or eliminate these

depressions;

2. identify the blocked parts (start with

gas outlet, connections to

appliances and bends); clean the

respective parts;

Repair measures are being taken in case of acute disturbances or during routine

maintenance work. Repair measures which go beyond routine maintenance work have to be

carried out by specialists, since the biogas plant owner in most cases does not have the

required tools and the necessary technical know-how. In any case, annual maintenance

service should be carried out by a skilled biogas technician.

74